Riblath

Range of expanded metal sheets for internal and external plaster key applications and anti-crack control.

Description and Application

Locusrite Riblath, stiffened by its longitudinal ribs, is produced for use on ceilings and partitions.

Specification

All galvanised materials are manufactured from steel to DX51.BSEN 10142 (g 275).

Stainless steel materials are manufactured from steel to EN 10088-2 grade 1.4301 (standard supersedes BS1449 Part 2: 1983 grade 304 S15).

Manufactured in accordance with BS1369 Part 1: 1987.

Riblath Product Range

Riblath comes in 500 sheets per pallet.

| Code | Material | Size (mm) | Thickness (mm) |

|---|---|---|---|

| GRL | Galvanised Steel | 2500 x 600 | 0.4 |

| GRR (Render Rib) | Galvanised Steel | 2500 x 600 | 0.4 |

| SSRL | Stainless Steel | 2500 x 600 | 0.4 |

Riblath

Installation

Fixing of Riblath Sheets

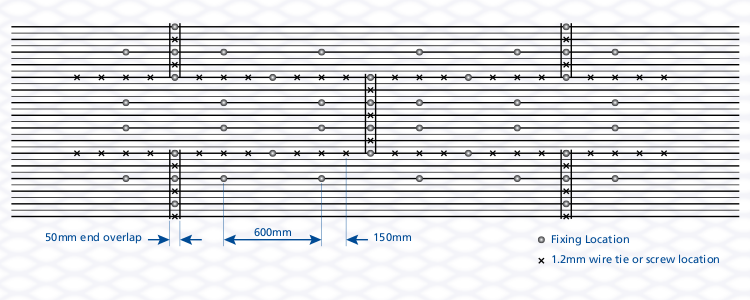

Riblath is fixed so that the tip of the rib is placed against the supporting background. The rib of the sheet should run at right angles to any supports. Ensure that sheets are overlapped by a minimum of 50mm end to end and by 25mm widthways and that the ribs are nestled together.

Timber Support

Riblath is fixed at each rib to timber supports using plasterers' nails or staples. Ensure that compatible corrosion resistant fixings are used, ie. do not use galvanised fixings for stainless steel.

Metal Support

Riblath is fixed at each rib to metal support using 1.63mm galvanised or stainless steel tying wire. When joining riblath sheets overlap the edge ribs and tie the edges with 1.22mm tying wire at 150mm centres.

Solid Background

Riblath can be fixed to a solid background using a suitable fixing which holds the ribs firmly against the background. Where sheets are installed vertically, fixings should be positioned through all ribs at 600mm centres to ensure adequate stability.